Introduction

Condensed molasses fermentation soluble (CMS) is the by-products generated from industrial production of amino acid, organic acid, alcohol, and yeast using the molasses as a raw material through microbial fermentation method (Stemme et al., 2005). During the processing of molasses, the sugar from it is consumed by the microorganisms to produce the end products which is CMS (Damron et al., 1980). This product maintains a good fragrance and minerals derived from molasses, also contains amino acids produced by microorganisms. This CMS contains 44.36% moisture, 32.02% crude protein, 0.46% crude fat, 11.39% Ash, 2.97% of non-protein nitrogen, and AAs which are 5.52% glutamic acid, 1.47% alanine acid, and 1.20% aspartic acid. It also contains some minerals such as chloride, potassium, and sulfur at levels of 3.04, 0.74, and 0.67% respectively. CMS has a freezing point of -40℃, it can be preserved during the winter period (Ha et al., 1996; Wadhwa and Bakshi, 2016). The concentrated liquid of such remains CMS contain the useful ingredients in animals’ feeds of 65 - 75% of dry matter and adequate nitrogen (Karalazos and Swan, 1977). Feed accounts for 65 - 75% of the total cost in the pig production (Singh et al., 2020). Due to the high price of molasses compared to CMS, utilization of CMS as an alternative feed to molasses could be an advantage and it has the dust removal effect which could minimize the environmental impacts caused by the disposal of sewage (Ma et al., 2021). This will result in lower feed costs and contribute to more cost-effective and environmentally friendly animal production (Yin et al., 2018). CMS can also be used to improve the quality of animal feeds. For example, Chen et al. (2020) found that the addition of CMS to the corn silage can be very promising for improving the quality and stability of corn silage. Thus, it could be reasonable to use CMS in swine feed as an alternative ingredient for molasses (Stemme et al., 2005; Kim et al., 2020). Kim et al. (2020) reported that adding 1.5% and 3% CMS to the diet of growing-finishing pigs showed significantly higher results than molasses. In laying hens fed with 2.5% of CMS levels, showed a significant increase in egg production (Damron et al., 1980). However, Lopez et al. (2011) reported that the addition of 100 or 200 g of CMS per kg in fattening lambs reduced the feed intake and growth rate, and increased the feed: gain ratio. In addition, Damron et al. (1980) who tested vinasse (75 g·kg-1) in the diet of broilers reports that no significant differences were observed in body weight and average daily feed intake. Vinasse is also known as concentrated molasses solubles (CMS). Fernández et al. (2009) and Stemme et al. (2005) reported that when 16 and 43% of CMS is added in pig feed there is a reduction in feed digestion. Previous studies assessing the effect of CMS on backfat thickness in growing pigs were inadequate. Condensed molasses soluble have been studied for use in ruminant feeds; however, information on its value as a non-ruminant feedstuff especially in swine is limited, until now, only few investigations dealing with the digestibility of CMS in pigs have been published. Therefore, the aim of this experiment was to evaluate the effect of condensed molasses fermentation soluble (CMS) to replace molasses on growth performance, nutrient digestibility, and backfat thickness in growing pigs.

Materials and Methods

Source of feed additive and ethical approval

The experiment was conducted at the swine research unit of Dankook University, Republic of Korea. The experimental protocols used in this study that describes the management and care of animals were reviewed and approved (DK-1-2007) by the Animal Care and Use Committee of Dankook University, Cheonan, South Korea. The CMS supplements used in this study were obtained from Sungkyun Biotech Co., Ltd. (Ansan, Korea).

Experimental design, animals, housing and diets

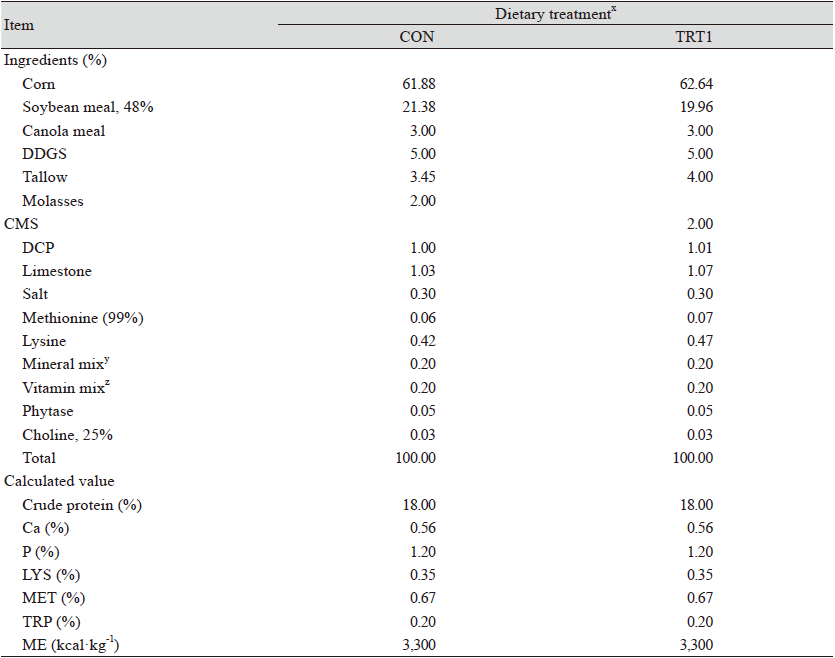

A total of one hundred and twenty crossbred ([Landrace × Yorkshire] × Duroc) growing pigs with an average initial body weight (BW) of 25.84 ± 1.60 kg was used in an 8-weeks trial. Based on the body weight and sex, pigs were randomly allocated into 1 of 2 dietary treatments. The dietary treatments were as follows: CON – corn soy bean meal based basal diet (control) + 2% of molasses; TRT 1 – CON + 2% CMS. Each treatment has 12 replicates with five pigs (3 gilts and 2 castrated barrows) per pen. Basal diets contained 3,300 kcal of metabolizable energy (ME)·kg-1 and 18.00% crude protein and they were formulated to meet or exceed the nutritional requirements of swine NRC (2012) (Table 1). All pigs were housed in an environmentally controlled room with a slatted plastic floor and each pen was provided with a one-sided self-feeder and a nipple drinker that allowed for ad libitum access to feed and water throughout the trial.

Sampling and analysis

At beginning and end of weeks 2, 4, 6, and 8 growing pigs individual body weight (BW) was measured using GL-6000s weigh machine (G-Tech International Co., LTD., Uijeongbu, Korea), whereas at the end of 2, 4, 6, and 8 the feed consumption and residual were weighed and recorded on a pen basis to monitor average daily gain (ADG), average daily feed intake (ADFI) and gain to feed (G/F) ratio.

On day 21 and 48, 2 g·kg-1 of Chromium oxide (Cr2O3) as an indigestible marker was mixed in growing pigs’ diets to calculate nutrient digestibility of dry matter, nitrogen, and gross energy. At the end of week 4 and 8, fresh fecal samples were collected from 2 pigs per pen (1 gilt and 1 barrow) by rectal massage, placed on ice box, transported to laboratory, and stored at -20℃ until analyzed. All feed samples and fresh fecal samples were dried at 70℃ in the forced air oven for 72 hours and then finely ground to pass through a 1 mm screen sieve. DM analysis were done following the methods outlined by the AOAC (2007). Chromium was examined through UV absorption spectrophotometry (Shimadzu UV-1201, Shimadzu, Kyoto, Japan). The GE was determined by measuring heat of combustion in the samples, using a bomb calorimeter (Parr 6100, Parr Instrument Co., Moline, IL, USA). Protein (N) content was determined by using a Kjeltec 8600 analyzer (Foss Tecator AB, Hoeganaes, Sweden). The following formula was used to calculate the nutrient digestibility: N digestibility = 1 - {(Nf × Cd) / (Nd × Cf)}, where: Nf – nutrient concentration in faeces, Nd – nutrient concentration in diet, Cd – chromium concentration in diet, and Cf – chromium concentration in faeces.

The back-fat thickness (BFT) of individual pigs were measured using a real-time ultrasound device (Piglog 105, SFK Technology, Herlev, Denmark). The mean value of the BFT was recorded for statistical analysis.

Statistical analysis

All the data were analyzed as a completely randomized block design using the GLM procedure of SAS (version 9.2, SAS Institute, Cary, NC, USA). When significant differences were identified among treatment means, they were separated using t-test. The pen was used as an experimental unit. The Variability in the data was presented as the standard errors of mean (SEM) and values of p < 0.05 were considered to be statistically significance. p <0.1 were considered as trends.

Results and Discussion

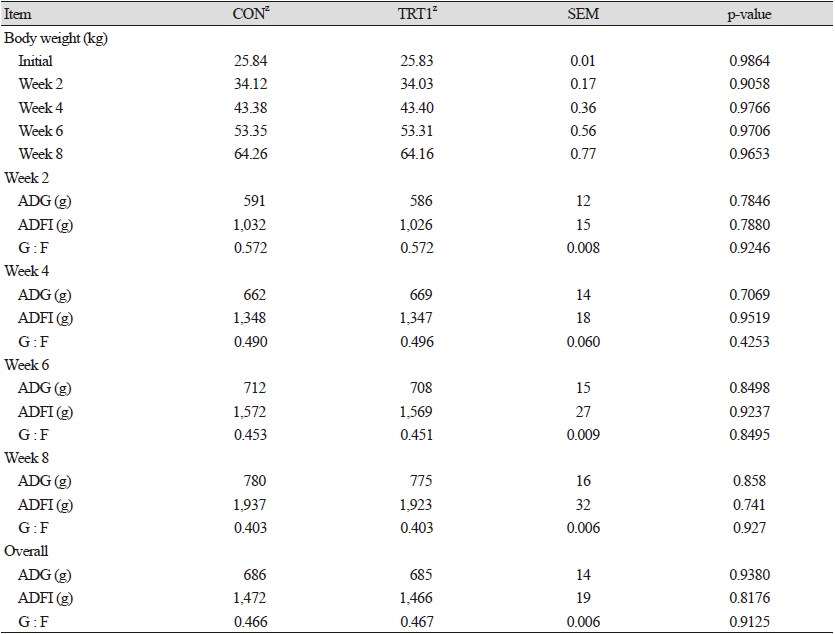

The effects of basal diets blended with CMS on the growth performance is shown in Table 2. In the present study, the body weight (BW), average daily gain (ADG), average daily feed intake (ADFI), and feed: gain ratio (G : F) were not affected in pigs fed CMS supplemented diet throughout the experiment (p > 0.05), which was in line with the findings of Damron et al. (1980) who found no significant difference on the BW gain and ADFI of broilers fed 10% of CMS. However, according to Kim et al. (2020) feeding of CMS improves the growth potential of growing pigs without compromising meat quality and may be used as an alternative to molasses in pig feeds, where the addition of 3% CMS showed a higher body weight than the control group. Zali et al. (2019) found that adding 12% CMS to the diet of male goat did not affect its growth performance. However, laying hens fed with 2.5% of CMS levels, showed a significant increase in egg production (Damron et al., 1980). While, Zali et al. (2017) demonstrated that feeding 10% CMS and 15% CMS diets significantly decreased BW and ADG of Holstein male calves. Based on the result that were reported by Waliszewski et al. (1997) on the trial of CMS on broilers showed that body weight and daily feed consumption increased linearly (p < 0.05) as the dietary content of CMS increased. The reason for these results could be nutrient digestibility, as nutrient digestibility was not affected in this current study either. Furthermore, the inconsistency in the findings of CMS supplementation in growth performance among different studies may also be associated with variation in animal species.

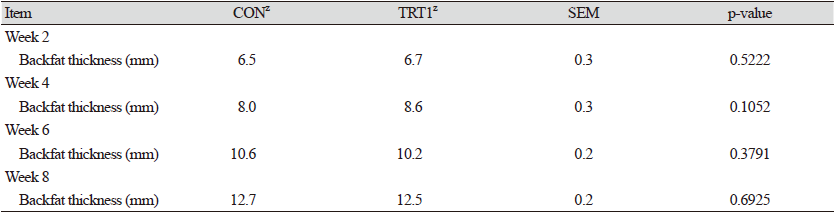

Back-fat thickness (BFT) is composed of water, collagen and lipids. Backfat thickness is an important parameter that should be considered when assessing age and body weight. Backfat thickness is also one of the significant parameters that should be considered when choosing pigs for breeding (Roongsitthichai and Tummaruk, 2014). Previous research has shown that pigs with a higher fat thickness reach sexual maturity faster than pigs with a lower fat thickness (Nelson et al., 1990). Zali et al. (2019) reported that adding up to 12% CMS to the feed did not affect male goat carcass performance. Table 3 displays the impact of diets combined with CMS on backfat thickness. There was no significant difference of BFT among the groups at weeks 2, 6, and 8, compared with the control group, however, the BFT of pigs supplemented with 2% CMS at week 4 showed tendency to increase (p = 0.1). Some studies reported that there is a quadratic relationship between backfat thickness and body weight (Noffsinger et al., 1959). However, others have reported a linear relationship between backfat thickness and body weight (Quijandria and Robison, 1971). Backfat thickness increases linearly with increasing body weight between 110 and 130 kg (Kim et al., 2005). From Kim et al. (2005) study we came to know that BFT is correlated with BW, however in the current study there were no significant difference observed on the body weight and from this we assume that the lack for BFT might be due to the lack of weight gain.

Table 3. The effect of condensed molasses fermentation soluble (CMS) on backfat thickness in growing pigs.

|

|

SEM, standard error of means. zCON, basal diet + 2% molasses; TRT1, basal diet + 2% CMS. |

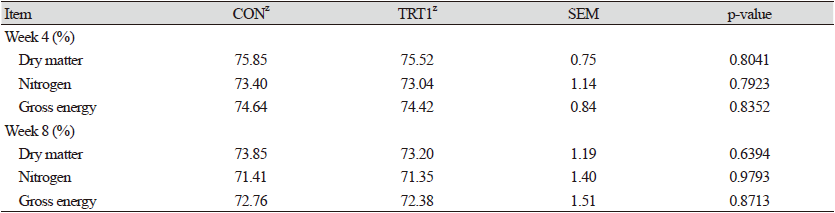

A higher nutrient digestibility is good for animal production (Zhao et al., 2017). The effects of diets mixed with CMS on nutrient digestibility are presented in Table 4. Nutrient digestibility of dry matter, nitrogen, and energy were not influenced by CMS. This is consistent with the results obtained by (Karalazos and Swan, 1977) who found that replacing barley with 20% CMS had no significant effect on the digestibility of dry matter in the sheep’s stomach, while adding 10% CMS had also no significant effect on the digestibility of energy in the rations. However, Ma et al. (2021) reported that apparent digestibility of dry matter, organic matter, and crude protein was higher in dairy cow fed diet contain 2% of CMS (p < 0.05). Also, Stemme et al. (2005) found that when 14 and 16% CMS were included in the diets of cattle and pigs, the digestibility of the organic matter from CMS was 73.5% in cattle and 72.3% in pigs. The conclusion reached is that since the digestibility of organic matter in cattle and pigs is > 70%, it is reasonable to use CMS in small amounts in these species. However, adding high levels of CMS to pig feed had reduced nutrient digestibility (Stemme et al., 2005). This may be due to the unexpectedly high content of sulphate (136 g·kg-1 DM) in CMS, which leads to osmotic-driven diarrhea and reduces the retention time of chime, this may reduce growth potential. These differences may be due to the amount of CMS in the diet, the animal's growth stage, and the environment in which the animal is raised.

Conclusion

This study confirmed the benefits of CMS which remains at the same level without compromising growth performance, nutrient digestibility, and backfat thickness. Through these results, CMS is expected to reduce feed costs due to lower prices, and that will help to increase the productivity and profitability of domestic pigs in the future.