Introduction

Pig farming is the largest sub-sector in the livestock industry; from this sector, large of global animal protein demand is fulfilled. The growing-finishing stage of pig production is the crucial period for fulfillment of global protein demand and has significant effects on profitability. About 55 - 75% of the total production cost of pigs is feed. After the realization of this, several industries and nutritionists were encouraged to search for strategies to improve animal growth performance by minimizing feed costs. The physical form (mash, pellet, extrusion, and crumble) of mixed feed is directly influencing pig production. Besides feed cost, the form and particle size of the feed in the swine diet have become critical factors in determining efficient feed utilization (Ball et al., 2015). Feed processing methods may change feedstuff’s physical, chemical, and nutritional values through several mechanisms (Kim et al., 2015). Processed feed has been broadly used in the commercial pig industry. Generally, mash and pellets were fed to young and growing pigs, respectively. Yang et al. (2001) reported that the use of crumble feed reduced feed costs by 15% per kg of body weight gain compared to a mash diet. Even Nguyen et al. (2017) reported that with the crumble feed feeding, growth performance significantly increased and reduced market day age, along with increased meat quality in growing-finishing pigs. On the contrary, Al-Rabadi et al. (2009) and Rojas and Stein (2015) reported that decreasing the particle size of feed improved the pig's performance. Besides, Goodband and Hines (1988) described that the fine particle size of feed has negative effects on the gastrointestinal health of pigs. Sampath and Kim (2023) reported that supplementations of 50% mash and 50% crumble feed increased feed efficiency and reduced feed costs without affecting production performance compared to mash-form feed.

Very recently, scientists have placed more emphasis on the pellet form of swine feed because it is widely accepted that the pellet form of pig diet improves average daily gain and gain to feed ratio (Kim et al., 2015). Crumble feed has recently become popular in the poultry industry (Nguyen et al., 2017; Khan et al., 2023). Jahan et al. (2006) reported that higher body weight gain was seen with crumble feed supplementation compared to mash and pellet feed. However, comparative studies of mash and crumble feed in growing-finishing pigs are still limited. We hypothesized that comparative effects of mash and crumble feed form could influence the growth performance, nutrient digestibility, and carcass grade in growing-finishing pigs. Thus, in this present study, we evaluate the comparative effects of mash and crumble feed used in growing-finishing pigs.

Materials and Methods

The research protocol was confirmed by the Animal Care Committee of Dankook University in South Korea (Protocol No. DK-2-2207).

Animals, diets, and experimental design

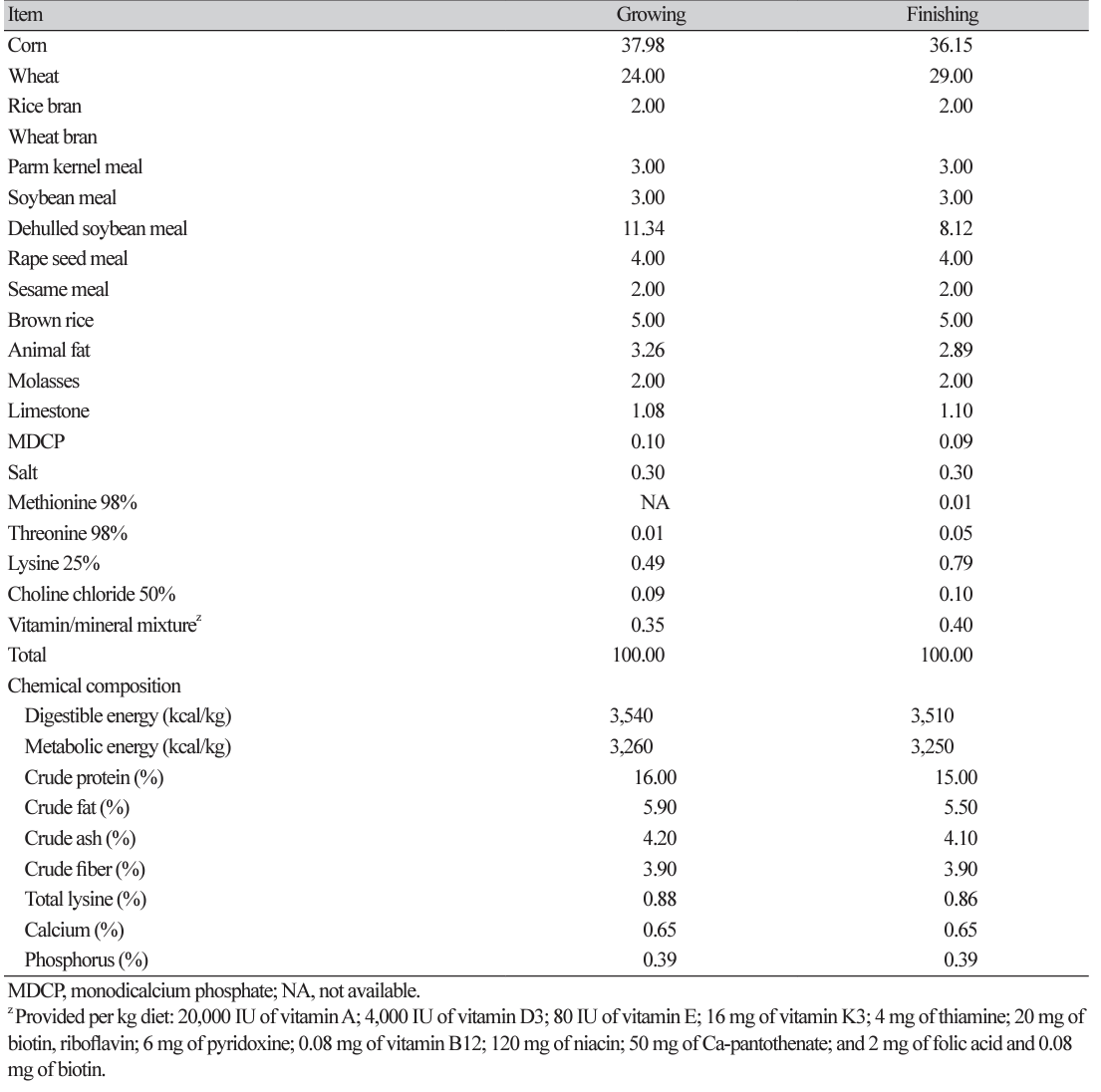

In total, 50 ([Landrace × Yorkshire] × Duroc) growing pigs with an initial body weight of (46.24 ± 3.57) kg were randomly allocated between two dietary treatment groups. Five replicate pens per treatment, including five pigs (2 males and three females) in each pen. Pigs were fed mash and crumble feed for 14 weeks of the trial period. All the experimental diets were formulated according to the following NRC (2012) guidelines (Table 1). All pigs were raised in an environmentally controlled shed where the floor was plastic slatted. The shed temperature was maintained automatically at around 24℃. Each pen was well arranged with an automatic feeder and a nipple drinker. Pigs were always allowed to feed and drink throughout the experiment.

Sampling and analysis

Individual pig body weight and feed consumption (for each pen) were recorded on the last day of weeks 4, 8, 12, and 14 to calculate the average body weight gain and gain to feed ratio (G/F). As an indigestible marker, 0.5% chromium oxide (Cr2 O3 ) was added to the pigs’ diet seven days before fecal collection to determine the digestibility of dry matter (DM), nitrogen (N), and energy (GE). Fresh fecal samples were collected from two pigs (1 male and 1 female) per pen through the rectal palpation method on the last day of weeks 1, 4, 8, 12, and 14. Immediately, the collected samples were shifted to the laboratory for analysis, and the samples were allowed to dry for 72 hours in a hot air-drying oven at 60℃, then ground well

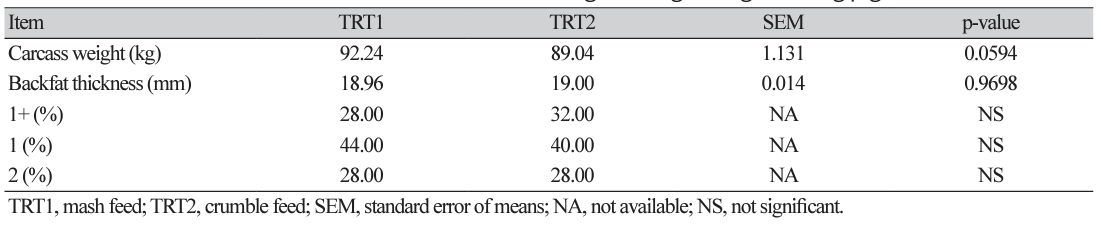

and filtrated using a 1 mm screen bolter. DM and N were analyzed by following the guidelines of AOAC (2005). The existing amount of chromium in feed and fecal samples was measured using UV-1201 spectrophotometry (Shimadzu Corporation, Japan). Using the TecatorTM Kjeltec8400 analyzer (FOSS, Denmark), the protein content (N) in feed and fecal samples was analyzed. The GE was calculated by measuring the combustion heat production in the samples using a bomb calorimeter (6400 Automatic Isoperibol Calorimeter, Parr Instrument Company, USA). The nutrient digestibility was calculated using ND = [1 - {(Nf × Cd)/(Nd × Cf)}], where Nf = nutrient concentration in feces, Nd = nutrient concentration in diets, Cf = chromium concentration in feces, and Cd = chromium concentration in diets. The back-fat thickness (BFT) of pigs was checked using an actual-time ultrasound instrument (Piglog 105, Frontmatec Group, Denmark) at the beginning and end of weeks 4, 8, 12, and 14. For statistical analysis, the mean value of BFT was used. Backfat thickness (mm), carcass weight, and carcass grade were measured. The quality of pork carcasses was graded into “Grade 1+”, “Quality Grade 1”, or “Grade 2”, based on characteristics such as marbling, lean color, and conditions of belly streaks (KAPE, 2010). Carcass BFT was adjusted to a live weight of 115 kg, as described previously (Ha et al., 2010).

Statistical analysis

All of the experimental data were analyzed using SAS (SAS version 9.4, SAS Institute Inc., USA) (general linear model technique) in a completely randomized block design. The pen was considered an experimental unit. Less than 0.05 was considered as a statistical significance.

Results and Discussion

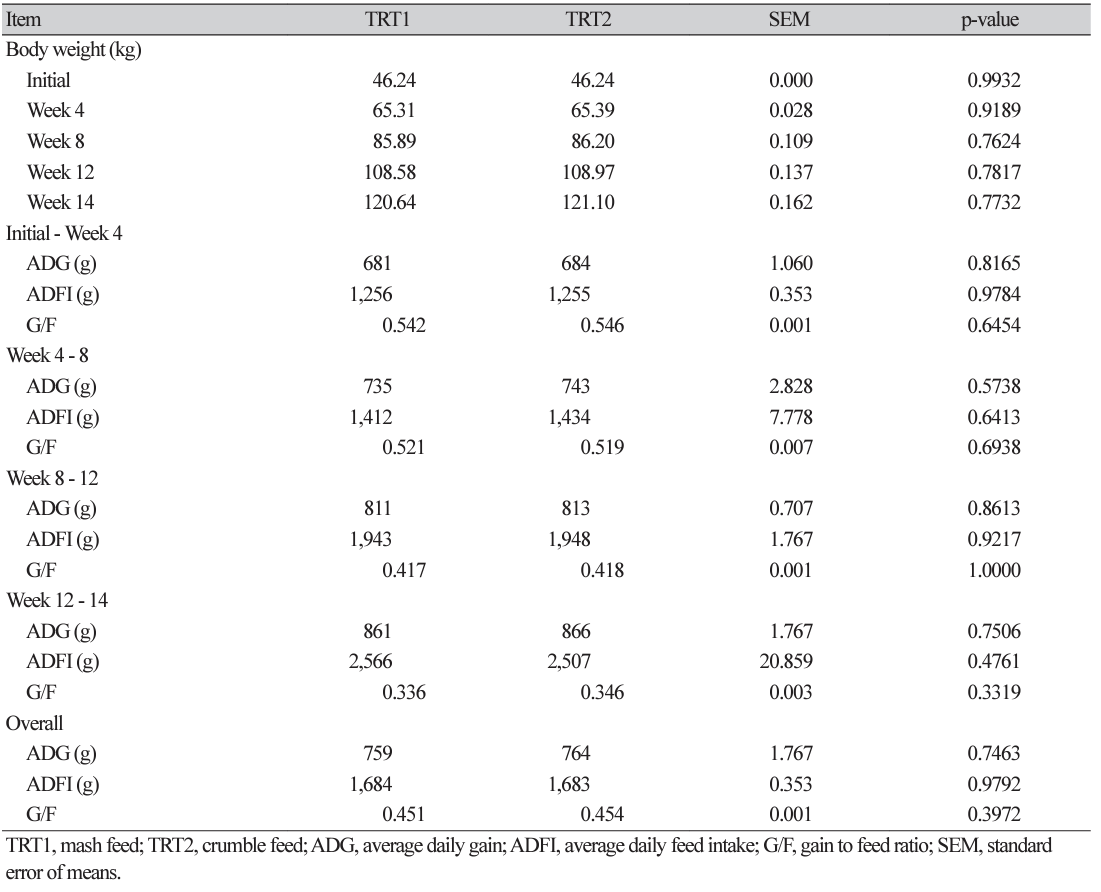

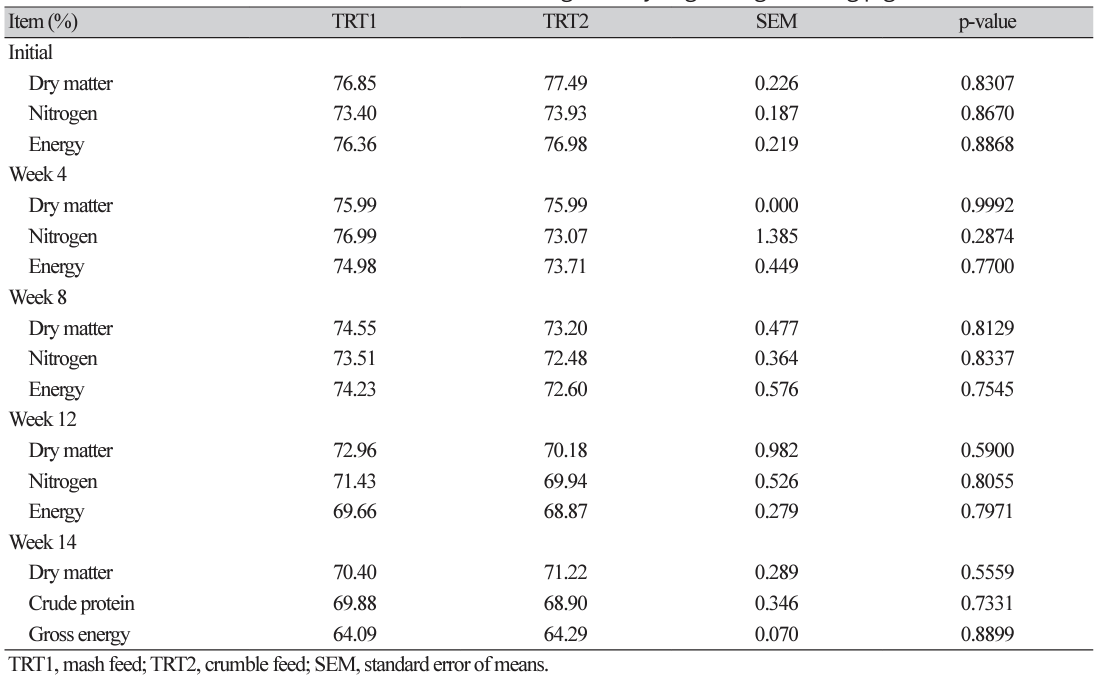

The form of feed (mash/crumble) is a crucial factor for production performance. For the past few decades, nutritionists have focused on improving the nutritional value of feed. Feed forms and their processing methods can improve the nutritional value of ready-made feed. Mash is one of the complete feed types where feed ingredients are finely ground and well-mixed to ensure a balanced diet for animals. It enhances the growth performances of animals and is more economical. Crumble is another type of ready feed that is prepared at the feed mill by pelleting the well-mixed feed ingredients and then crushing the pellet to a consistency coarser than mash (Sureshkumar and Kim, 2021). Crumble feed production costs are comparatively higher than mash due to its higher processing costs. Even then, crumble feed is getting more attention in broiler productions because of its convenience. Generally, mash feed is produced specially for young animals for their better body development and muscle building. It contains high-quality protein and a higher level of amino acids, which are also helpful for the rapid growth and development of pigs. Recently, extruder and expander processing getting more attention because some previous researches reported that nutritional value may altered by extruder and expander conditions for an example degree of temperature. Crumble feed significantly increased the growth performance of growing-finishing pigs compared to mash feed (Nguyen et al., 2017). Additionally, Sampath and Kim (2023) stated that supplementation of 50% mash and 50% crumble feed enhanced the feed efficacy and reduced the feed cost compared to only mash feed. In this study, mash and crumble form of feed had no significant effects on average daily gain (ADG), feed intake (FI) and G/F in growingf inishing pig throughout the experiment (Table 2). Similarly, Kim et al. (2015) reported that crumble and mash feed had no significant effects on growth performances in sows. Additionally, Sampath and Kim (2023) reported that mash and crumble feed had no significant differences on body weight, daily gain, daily feed intake in growing-finishing pig. The possible reason for no significant effects would be the different nutritional source, manufacturing technology or feed structure, farm environment and management practices etc. But the actual mechanism is still uncleared. The effects of mash and crumble feed form on nutrient digestibility of growing-finishing pig is summarized in Table 3. There were no significant effects in the nutrient digestibility of DM, N, and GE of pigs throughout the experiments. Similarly, Sampath and Kim (2023) reported that no significant effects on nutrient digestibility on DM, N and GE in growing-finishing pigs by the using of mash Vs 50% mash and 50% crumble. However, Owsley et al. (1981) reported that reduction particle size of sorghum from 1262 μm to 802 μm to 471 μm has enhanced the apparent nutrient digestibility of DM, starch, N and energy measured at the marginal ileum of the total digestive tract of growing pigs. In our best knowledge very, limited study has been carried out on animals fed mash or crumble feed form that enhance the nutrient digestibility parameter. We speculate that no significant on growth

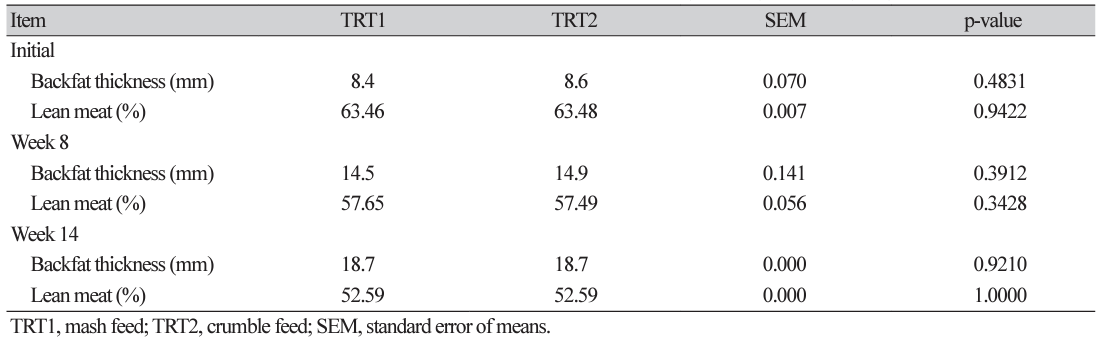

performance is probably due to lack of nutrient digestibility, while the main cause is still unclear, thus it needs further study. In our study, no significant was observed in back-fat thickness (Table 4), which was constant with the findings of Sampath and Kim (2023) and Nguyen et al. (2017). Moreover, Sampath and Kim (2023) and Pettersson and Bjórklund (1976) stated no significant differences in carcass quality (Table 5) in pigs fed mash and crumble feed.