Introduction

Pigs should be handled appropriately prior to slaughter, both from a welfare and pork quality standpoint. As a part of its purpose, lairage provides storage of animals aimed at allowing them a respite from the stress of transport and loading (Faucitano, 2010). Lairages serve several functions, such as providing post-mortal inspections and providing a reservoir of animals to ensure the slaughter line runs efficiently (Weeks, 2008). Also, lairages help pigs recover from the stress of handling and transport from the farm or market (Faucitano, 2010). According to Warris et al. (1994), high stress lairage conditions can contribute to the accumulation of transport stress in pigs, causing poor pork quality and still stressed pigs at slaughter. One of the factors affecting the lairage environment in which pigs can rest with less stress is the stocking density (FAWC, 2003). In addition, temperature variations affect the pig’s ability to maintain body temperatures, leading to poor meat quality (Santos et al., 1997). According to Gispert et al. (2000), pigs stocked with high lairage density showed higher skin damage scores than those stocked with low lairage density. However, previous studies reported that lairage density did not affect on blood stress indicators and meat quality (Carr et al.,2008; Dokmanović et al., 2014). Also, Santos et al. (1997) reported that environmental temperature affects the incidence of PSE (pale, soft, exudative) meat.

However, there is a lack of study on the optimal density according to temperature in the lairage. The objective of this study was to investigate meat quality, blood profile and behavior changes according to lairage stocking density in high temperature.

Materials and Methods

The protocol for this study was reviewed and approved by the Institutional Animal Care and Use Committee of Chungbuk National University, Cheongju, Korea (approval no. CBNUA-2047-22-01).

Animals, pre-slaughter conditions and treatments

Between June 2023 and August 2023, a total of 923 crossbred pigs of mixed sex with same genetics ([Yorkshire × Landrace] × Duroc) were transported from the one commercial finishing farms to the one commercial slaughterhouse. Pigs were transported through 15 journeys with travelling a distance of 40 km. On arrival, pigs were moved to lairage pens and rested in different density. Density treatments were as follows: LD, low density (lower than 0.5 m2/100 kg); ND, normal density (0.5 m2/100 kg to 0.83 m2/100 kg); HD, high density (higher than 0.83 m2/100 kg). Air temperature treatment was as follows: HT, high temperature (higher than 24℃). This design was proposed emphasizing the control of all the factors associated the experimental treatment (genotype, fasting, handling, bedding, distance, and lairage) in order to compare only the effect of lairage density and air temperature.

Meat quality measurements

Pig carcasses were graded with the Korean Pig Carcass Grade System. The conductor grades are as follows: 1+ grade (carcass weight: 83 to 93 kg, backfat thickness: 17 to 25 mm), 1 grade (carcass weight: 80 to 98 kg, backfat thickness: 15 to 28 mm, the rest except for 1+ grade), 2 grade (Ranges of carcass weight and backfat thickness that do not correspond to 1, 1+ grade). The hot carcass weight was measured on an electronic scale 45 minutes postmortem and expressed in integer kg units. The left half carcass was used to measure the backfat thickness. The backfat thickness between the last thoracic vertebra and the first lumbar vertebra and that between the 11th and 12th thoracic vertebrae were measured with a ruler. Hot carcass weight and backfat thickness were measured and calculated as (backfat thickness [mm]/hot carcass weight [kg]). Pig losses were measured by observing and classifying fractures and bruises after the pigs were unloaded after transport.

The moisture, protein, and fat content (%) was determined according to Association of Official Analytical Chemists (AOAC, 2000). The pH was measured after adding 50 mL of distilled water to 5 g of the left carcass loin. All samples were homogenized for 30 seconds using a homogenizer (Stomacher® 400 Circulator, Seward Ltd., UK), and then measured with a pH meter (Orion Star™ A211 pH Benchtop Meter, Thermo Fisher Scientific Inc, USA) calibrated in phosphate buffer at pH 4, 7, and 10. In meat color, left carcass loin was measured with a Spectro Colorimeter (Model JX-777, Color Techno System Corporation, Japan) standardized on a white plate (L*, 89.39; a*, 0.13; b*, -0.51). At this time, the light source was used a white fluorescent lamp (D65). Color values were expressed as L* (lightness), a* (redness), b* (yellowness). Drip loss (DL) was assessed using the filter paper wetness (FPW) test. DL was measured as the weight loss during suspension of a standardized (40 - 50 g and approximately 30 mm × 60 mm × 25 mm) muscle sample (in an airtight container over 48 h at 4℃). DL was expressed as a percentage relative to the initial weight. Cooking loss (CL) was determined with Oliveira et al. (2014) methodology. For determination of CL, a meat sample of 1 cm3 was cut from each animal. After weighing, the sample was stored for 24 h at 4℃ before heat treatment in a water bath at 85℃ for 10 min resulting in a core temperature of approximately 75℃. Subsequently the meat sample was lightly dabbed and weighed. CL value was measured as the ratio (%) of the weight of the initial sample to the weight after heating the sample. Sensory color was evaluated by 5 trained panelists. The sensory color was followed as: score 1 (pale), score 2 (grayish pink), score 3 (reddish pink), score 4 (purplish red), score 5 (dark). Marbling was evaluated by 5 panelists according to the detailed criteria for grading of livestock products. Marbling score was followed as: score 1 (practically devoid), score 2 (slight), score 3 (modest), score 4 (slightly abundant), score 5 (abundant).

Pork quality classes measurements

The intra-measurement coefficients of variation for meat quality parameters were below 10%. Pork quality classes (PSE, pale, soft, and exudative; RSE, red, soft, and exudative; RFN, red, firm, and non-exudative; PFN, pale, firm, and nonexudative; DFD, dark, firm, and dry) were determined using pH values measured 24 h postmortem, DL variations, and light reflectance (L*), with the perimeter values pH ≤ 5.8, L* ≥ 50, and DL ≥ 5% according to Koćwin-Podsiadła et al. (2006).

Behavioral and status observations and blood profile

During transport, behaviors were continuously recorded using cameras (Intelbras VMH 1010 D HD 720p, Intelbras SA, Brazil), installed on the ceiling of the trailer. During transport, the number of pigs in each posture (lying, standing, sitting, aggression, and overlap) was recorded. As the compartment group was not always entirely visible by the camera, only recordings with at least 7 visible pigs in each group were used for the analysis. Cortisol, lactate and glucose samples were taken after unloading at the lairage. Blood samples were collected from 10 pigs in each group for the determination of concentration levels of cortisol, glucose and lactate. At least 3 mL of blood samples were taken from jugular vein. After collection, serum samples were centrifuged at 3000 × g for 20 min at 4℃. Thereafter, the blood sample tubes were stored in a -20℃ refrigerator until analysis. The cortisol values in both transported and control pigs were measured using radioimmunoassay Coat-A-Count cortisol kits (Catalog number-TKCO5, Siemens Medical Solution Diagnostics, USA). Serum glucose was analyzed using an automatic Konelab analyser (Thermo Clinical Labsystems Oy, Finland) according to the manufacturer’s instructions. Lactate levels were measured using a GM7 Analox analyser (Analox Instruments Limited, UK).

Statistical analysis

Data generated were subjected to a one-way Analysis of Variance using SAS software (SAS Institute Inc., USA). Statistics for each factor were analyzed using general linear model (GLM) procedures of SAS. Significantly (p < 0.05) different means among the variables were separated using Tukey’s multiple range test as contained in the same statistical package.

Results and Discussion

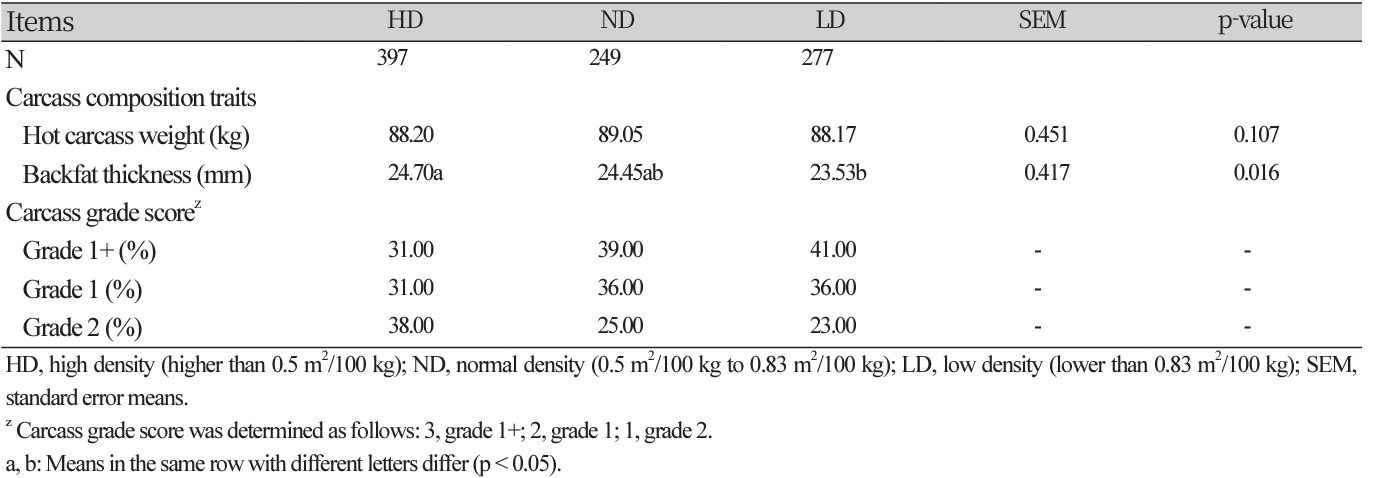

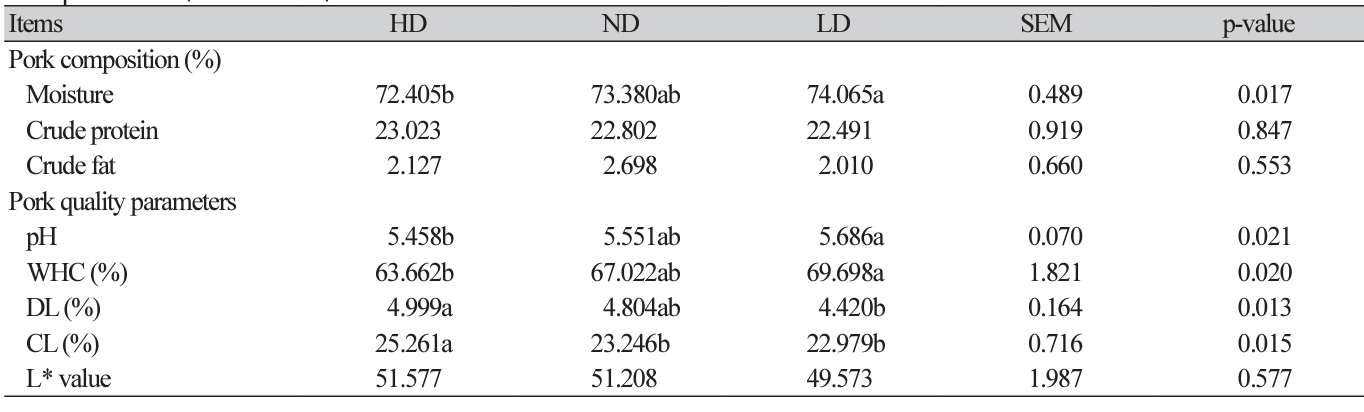

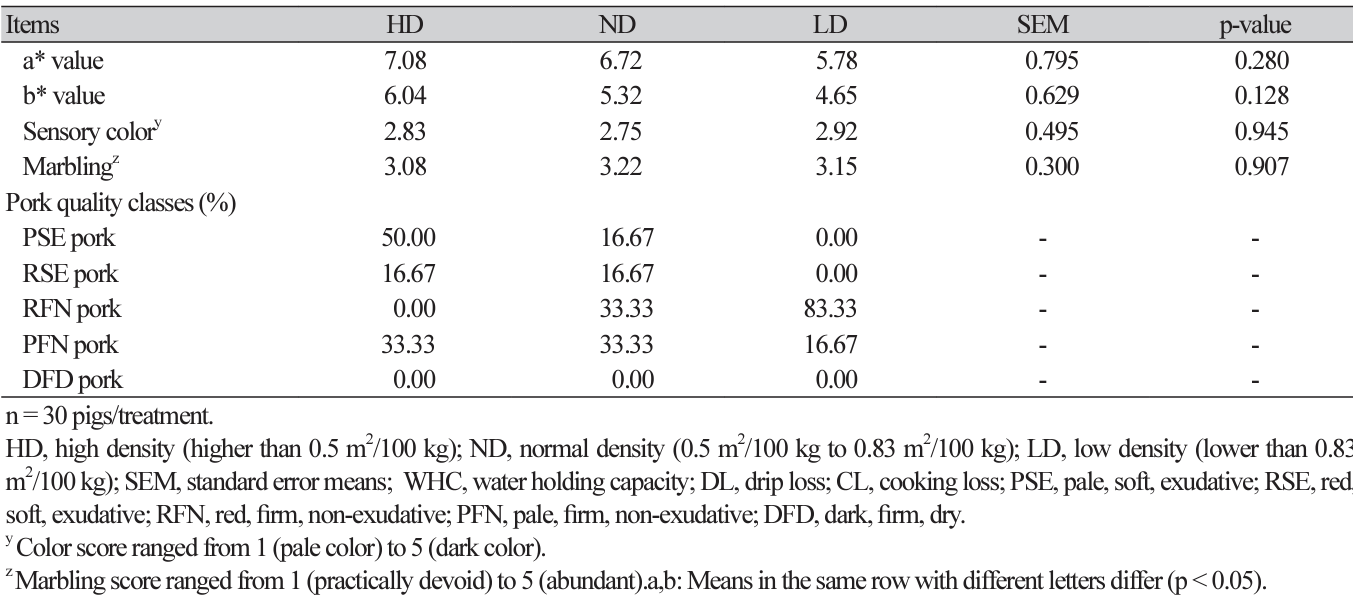

The current study provides the results on pork quality and blood stress in pigs according to handling method in lairage based on animal welfare. Table 1 shows the effects of lairage density on Carcass composition and carcass grade in HT. In HT, pigs stocked with LD showed lower backfat thickness than those stocked with HD. In HT, pigs stocked with LD showed higher incidence of Grade 1+ than those stocked with HD. Table 2 shows the effects of lairage density on pork composition and pork quality parameters in HT. In HT, pigs stocked with HD showed lower moisture content than those stocked with LD. Pigs stocked with LD showed higher pH, WHC (water holding capacity), and lower DL and CL than those stocked with HD. According to Xu et al. (2020), a low pH value in meat means more intense glycolysis occurs postmortem, which results in increased DL because muscle proteins are denatured. Also, Xu et al. (2023) reported that denaturation of protein would be decrease WHC of meat. Mun et al. (2022) reported that backfat thickness of pig is higher in HT than low temperature. Similar to this result, our results showed pigs stocked with HD showed higher backfat thickness than those stocked with LD in HT. The stress of pre-slaughter can also affect meat pH, which impacts meat quality. Gonçalves Vero et al. (2023) reported that pigs handled with HD showed higher pH those handled with LD in summer. Also, Arsenoaia and Mălăncuș (2023) reported that pigs handled with high levels of stress can lead to a rapid decline in muscle pH and cause PSE meat. In our study, HD group had numerically higher incidence of PSE than LD group.

Table 2

Effects of lairage density on pork composition and pork quality parameters in high temperature (continued).

Table 2

Effects of lairage density on pork composition and pork quality parameters in high temperature.

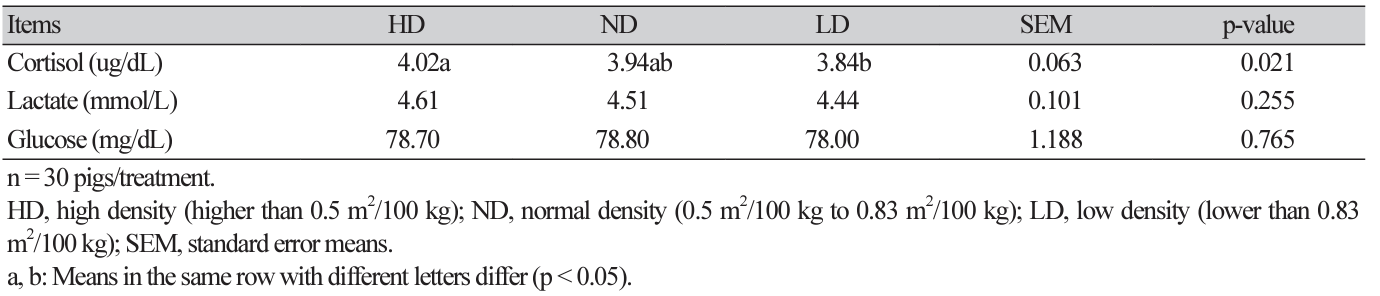

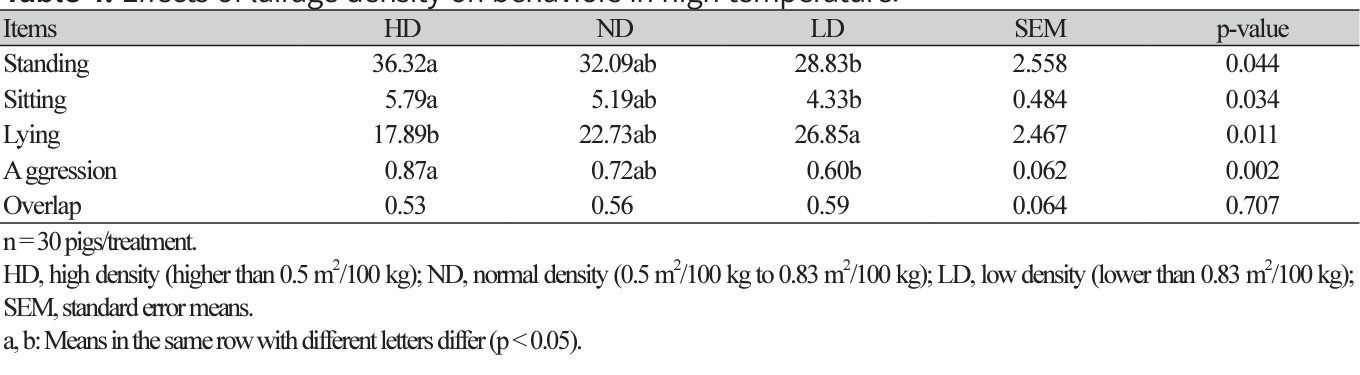

This result is consistent with previous studies that the pork quality subjected to acute stress could be lowered (Driessen et al., 2020). It would be possible that acute stress can increase the incidence of PSE meat by lowering the pH of pork and reducing its WHC (Čobanović et al., 2023). Table 3 shows the effects of lairage density on blood profile in HT. In HT, pigs stocked with LD showed lower cortisol level than those stocked with HD. Table 4 shows the effects of lairage density on behavior HT. In HT, pigs stocked with LD showed higher lying posture ,and lower sitting, standing and aggression than those stocked with HD. A physiological response to stress is the activation of the hypothalamic pituitary adrenal axis, which increases cortisol levels. So, cortisol level is served as an indicator of acute stress. Dalla Costa et al. (2019) reported that pigs handled with HD showed higher serum cortisol levels than those handled with LD. The postures of pigs are usually indicated as a discomfort of pigs suffering from heat stress or limited space availability to rest (Urrea et al., 2021). According to Grandin (2007), lying posture is an important tool within behavioral thermoregulation. Gerritzen et al. (2013) reported that higher proportion of pigs sitting when stocked at a greater density. Also, pigs stocked with HD showed higher aggressive behavior than those stocked with LD in summer (Gonçalves Vero et al., 2023). It would be pigs subjected to high air temperature with a high stock density suffered from critical acute stress due to the narrow space in which they were not able to lie down to conduct heat away from their body.

Therefore, it is recommended to lairage pigs at a density lower than 0.5 m2/100 kg in high temperature.

Conclusion

Pigs exposed to high stock density (lower than 0.5 m2/100 kg) in high air temperature during pre-slaughter caused acute stress and lead to PSE pork incidence. Based on obtained results, stocking of too high (lower than 0.5 m2/100 kg) density is generally not good for meat quality and animal welfare at high temperatures.