Introduction

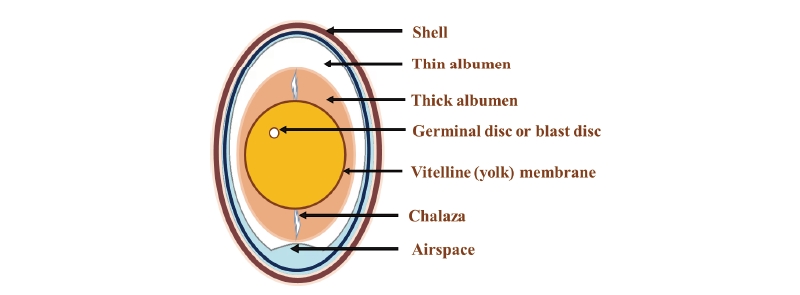

Freshness plays a vital role in determining the quality of food that we consume in our everyday life (Rahman et al., 2018). Essentially, it indicates how well the food retains the same physical and chemical attributes from the time of harvest until consumption. Improving the production ability can able to satisfy the rising demand of human consumption (Lee et al., 2017). While purchasing any product we mainly focus on the quality as it directly concerns human health (Ahmed et al., 2017). Several physical and chemical changes have been recorded in eggs after laying. Eggs are an essential part of the human diet and are an essential source of highly digestible proteins, lipids, minerals, and vitamins (Fisinin et al., 2008). Eggs are processed into various products (i.e., liquid, frozen, and dried egg products) for use in the food-service industry or as ingredients in a plethora of recipes (Froning, 2008). Fig. 1 shows the composition of eggs which mainly consists of a cuticle layer, pore canals, a hard shell, two shell membranes, egg white or albumen, yolk, and vitelline (yolk) membrane (USDA, 2000). The major constituents of albumen or egg white are water (≥ 91%) and protein (≥ 10%), followed by carbohydrates (0.4 - 0.9%) that exist in free form, usually as glucose, or forming complexes with proteins such as glycoproteins that contains mannose and galactose units (Wu, 2014) and also composed of lipid (0.03%) and ash (0.5 - 0.6%) (Sugino et al., 1997). Furthermore, the yolk constitutes 36% of the total egg weight which is mainly composed of approximately 51% water, 16% proteins, 32.6% lipids, 1.7% minerals, and 0.6% carbohydrates (Wu, 2014).

Egg handling and storage practices have a significant impact on the freshness of eggs that reaches to the consumers. Besides, existence of natural mineral also affects the quality of eggs (Oh et al., 2018). These quality attributes mainly divided into two categories: external and internal quality characteristics (Monira et al., 2003). External quality traits include weight, size, shape, shell thickness, shell color and shell strength (Bain, 2005) while internal features of an egg include albumen quality, yolk quality and airspace size. However, during storage, several factors such as the duration of storage time and temperature may affect the quality attributes, leading to the deterioration of egg quality. Therefore, it is important to know the storage life under specific environmental conditions, during which no deterioration in quality occurs (Tiwari and Jha, 2017). Several parameters are affected during storage, i.e., Haugh unit (HU), pH, airspace volume, etc. which may result in deterioration of quality to a level not suitable for human consumption. The internal quality of the egg worsens with longer storage times because carbon dioxide transfer through the shell is favored by temperature and humidity (Oliveira, 2009). Storing eggs for longer durations results in several physical and chemical changes. As such, the air cell height and the HU, an index related to the thickness of the albumen and the mass of the egg (Haugh, 1937), are strongly dependent on the age of the egg. Air cell height is used in the European Community (EEC, 1989, 2003), and HU is used in the U.S. to discriminate the freshness of shell eggs.

Furthermore, these quality attributes as the indicator for the freshness of eggs sometimes concerns or might be affected when the eggs are washed or unwashed. Several studies have analyzed the quality of eggs but a comparative analysis of washed and unwashed eggs has not been conducted in terms of parameters such as HU, pH, eggshell strength, etc. The major advantage of washing eggs is to reduce the microbial growth on the shell surface (Messens et al., 2011) which can minimize the risk associated with the presence of foodborne pathogens and improves the visual appearance. Further, the decline of microbial growth can reduce the risk of cross-contamination to other foods. However, there are several disadvantages of egg washing such as the potential damage to the physical barrier namely cuticle layer. This layer is responsible for trans-shell contamination with bacteria and can reduce moisture loss (Wang and Slavik, 1998), which can reduce the quality of eggs during storage.

Thus, the purpose of this research is to evaluate the effects of storage time (0 - 8 weeks) and temperature (5, 10, and 25℃), and conduct a comparison between washed and unwashed eggs. Even though several researches have been already published on egg quality but comparison studies for washed and unwashed eggs based on quality parameters are limited. Besides, it provides the fundamental information on how egg washing (before storing) affects the external and internal attributes such as HU, pH, egg shell strength, etc. that has been measured in this study.

Materials and Methods

Egg collection and treatment

For this study, quality attributes have been measured using washed and unwashed egg samples which were purchased from the egg research institute in South Korea and stored in the incubator at 5, 10, and 25℃ for different storage times (ranging from zero to eight weeks). Week zero (fresh eggs) sample measurements were made immediately after treatment. During each week of storage, eggs were randomly selected to undergo testing to determine their quality aspects namely: HU, airspace volume, eggshell strength, pH, and microbial profile.

Sampling procedure

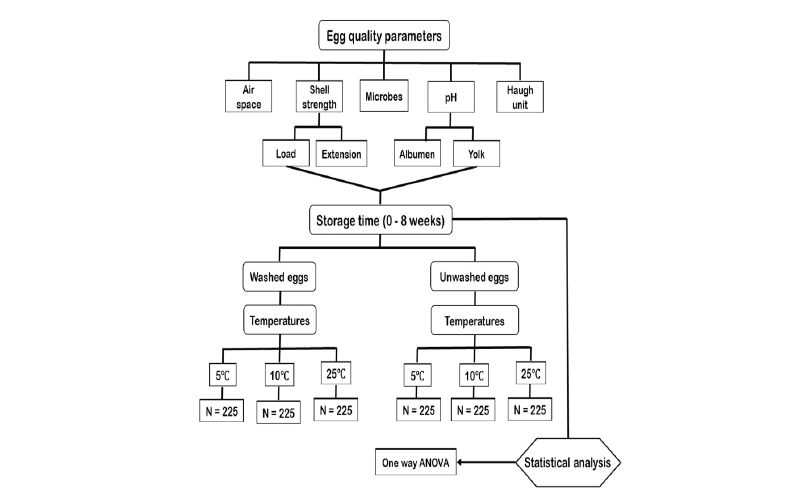

The experimental procedure for both washed and unwashed samples is shown in Fig. 2. Washed and unwashed egg samples were chosen for measuring aspects of quality through a random selection procedure. For the measurement of each parameter, 20 washed and an equal number of unwashed egg samples, stored at 5, 10, and 25℃ were used per week (0 - 8 weeks). Week zero sample analysis was conducted the day after the treatment were assigned to assure that all the egg samples were equilibrated to the storage temperature, as the eggs quality factors are highly influenced by the storage condition (Keener et al., 2006). A total of 540 washed and 540 unwashed eggs were used for measuring HU, eggshell strength and pH. Moreover, five out of every 20 egg samples were chosen per week from both washed and unwashed groups at three different temperatures for the analysis of microbiological values (135 of each washed and unwashed samples). To measure air space size, 5 washed and 5 unwashed samples were used per week for three different temperatures (a total of 135 washed and 135 unwashed samples).

First, the eggs were weighed, which leads the samples to the universal testing machine (UTM) test. The same samples were then broken on a clear surface to measure the HU values, followed by separation of the albumen and yolk for the measurement of pH values, and were further subjected to microbiological analysis. The whole procedure was conducted using one sample at a time for the measurement of all quality parameters except for the air space size.

Egg quality experimental traits

Haugh unit (HU) determination

HU values were determined during each week of storage for both washed and unwashed eggs. Along with HU, egg weight and albumen height were determined using technical services and supplies (TSS) egg quality tester. Randomly chosen samples were broken on the clear surface of the tester and a tripod was used for measuring the height of the albumen in order to measure the HU values (Haugh, 1937), which were calculated using the following equation:

HU = 100 × log (H + 7.57 – 1.7 W 0.37)

where H is the albumen height (mm), and W is egg weight (g).

Airspace volume

The destructive method was applied for extracting the information regarding the airspace volumes in all samples. Firstly, all samples were weighed and then a light source was used to check the position of the airspace in the eggs. A small hole was made on the surface of the eggshell, and the empty air space area was filled with water using a small syringe. The samples were then weighed. Lastly, in order to calculate the air space volume, the initial weight of the samples was subtracted from the final weight.

Eggshell strength

The firmness of eggshell was measured by using a Universal Instron Texturometer (Model 3343, single-column, Instron Corp., Norwood, MA, USA) to perform the compression tests by using a probe of 6 mm in diameter at a speed of 6 mm/s for penetrating the egg samples. All the tested eggs were then placed on the fixed plate and then ruptured, which then allowed for the measurement of the maximum load (N) and extension (mm) values.

pH determination

The pH of the albumen and the yolk were measured using a pH meter (Oasis Scientific, Inc., USA). The pH meter was first standardized using a buffer solution of pH 4 and 10. The albumen and yolk were separated into clean beakers for the measurement of pH values. The electrode was then rinsed with de-ionized water and dipped into the homogenate allowing sufficient time for stabilization between the measurement of pH values.

Microbiological analysis

The total plate counting method was performed for the microbiological analysis. All washed and unwashed egg samples were initially stored at 4℃ Prior to the plate counting method, 100 mL of agar medium was then spread on the plate post in which egg samples were incubated at 37℃ on these plates for about 16 hours. Later, the number of colonies formed in the colony-forming unit per mL (CFU/mL) was multiplied by 10, and finally, the microbe population in the plate were counted.

Statistical analysis

Analysis of variance (ANOVA) was used to statistically evaluate the two sets of samples (washed and unwashed) at different storage time (0 - 8 weeks) and three different temperatures (5, 10, and 25℃). One-way ANOVA was applied to analyze the significant difference among the samples. Tukey’s test was used to test the difference between the means for all quality parameters. The significance level was chosen for all analysis was p < 0.05. All the statistical analysis was performed using Origin Pro 8.1. A total of 675 washed (225 samples for each temperature) and 675 unwashed (225 samples for each temperature) eggs were analyzed for each replicate.

Results and Discussion

Changes in HU during storage

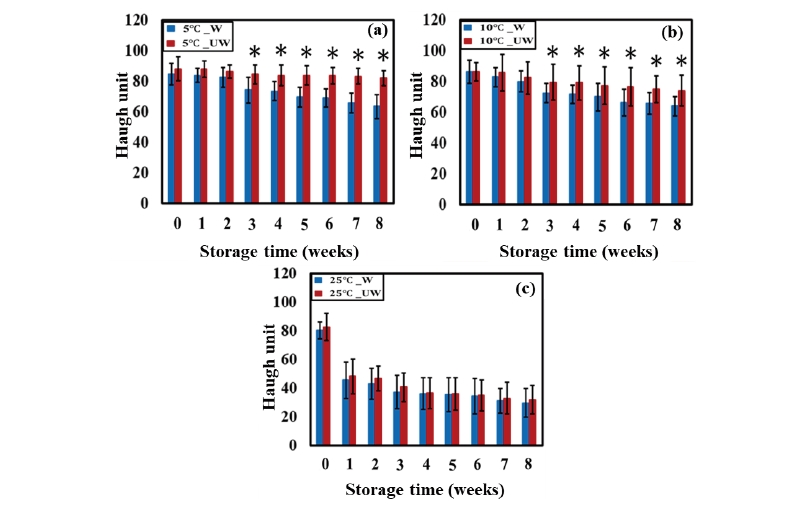

The internal and external egg quality traits are essential properties for quality determination of washed and unwashed eggs. The HU is critical measure in egg grading and is highly influenced by the albumen quality, particularly the albumen height. The effect of storage period on the internal egg quality traits depicted as a graphical representation of the changes in HU for egg samples during storage time (0 - 8 weeks) at three different temperatures i.e., 5, 10, and 25℃ is shown in Fig. 3. A significant difference (p < 0.05) was obtained for 5 and 10℃ after two weeks of storage while no changes were observed at 25℃ in washed and unwashed samples (asterisks in Fig. 3 represent significantly different egg samples).

The decline in the HU of the eggs during storage is due to the breakdown of carbonic acid in the egg white which produces carbon dioxide and water. In addition, the content and nature of ovomucin also determine albumen height (Silversides and Budgell, 2004). Further, the breakdown of the ovomucin-lysozyme during storage also reduces the thickness of albumen, which affects the HU values. Therefore, experimental result concluded that at high temperature the values extracted for HU have no significant difference, as for both washed and unwashed are affected by high temperature (25℃) for entire storage time. While, a significant deterioration in HU values that started after two weeks was observed for both washed and unwashed eggs at a lower temperature (5 and 10℃). Thus, values of HU are significantly different (p < 0.05) for a lower temperature in comparison with high temperature for all storage environmental conditions.

Changes in airspace volume during storage

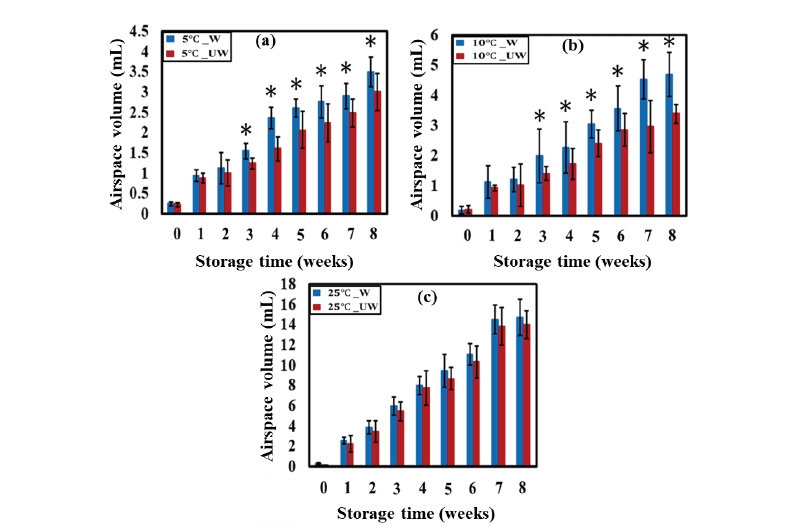

The volume of airspace was also affected during the prolonged storage of eggs at different temperatures. This increment was obtained due to the removal of the cuticle layer from the egg shell. In a study, it was shown that carbon dioxide affects the airspace volume over the time of storage (Tona et al., 2002). An illustration of washed and unwashed egg samples is shown in Fig. 4 where the increase in the in airspace volumes at the storage time and three tested temperatures. Highest airspace values were extracted from 25℃ for both washed and unwashed samples at different storage time and temperature. Stored washed and unwashed egg samples showed a significant difference (p < 0.05) after two weeks at 5 and 10℃, while no changes were seen at 25℃ (asterisks in Fig. 4 represent significantly different egg samples).

Loss of carbon dioxide and inflow of oxygen into the eggs through the pores in the eggshell result in the creation of air bubbles due to air displacement moisture and carbon dioxide. This causes the egg to float when placed in water due to loss of weight (Hassan and Aylin, 2009). Therefore, this study suggested that airspace values are profoundly affected by the storage environment, probably because of the loss of water and carbon dioxide through the shell (Ragni et al., 2007). For this research, maximum airspace values (Fig. 4) were extracted at 25℃ where both washed and unwashed samples were under the effect of storage time and temperature. While a significant change was observed after two weeks at low temperature (5 and 10℃) in washed and unwashed eggs. Thus, the airspace values are highly influenced at low temperature while no significant changes (p < 0.05) were extracted at a higher temperature in washed and unwashed eggs under all storage conditions.

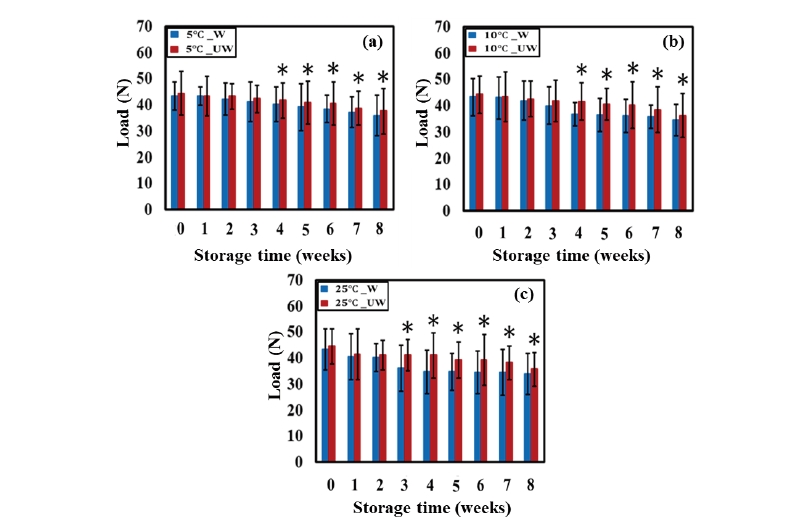

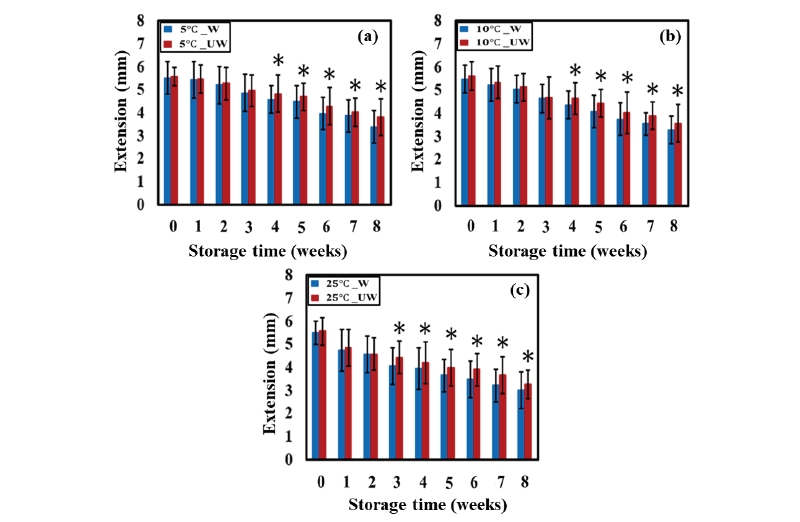

Changes in eggshell strength during storage

Measuring the eggshell strength is also important, as it also a significant factor that affects the quality of eggs for both washed and unwashed eggs. The graphical representation for compression test is presented in Fig. 5 and 6 for extracting the values of maximum load and extension. Extracted values using ANOVA for maximum load and extension shows a decline for different storage time and temperature. A significant difference (p < 0.05) was obtained for low temperature (5 and 10℃) after third weeks, while at high temperature (25℃), the significant difference was obtained after 2 weeks for maximum load and extension (asterisks in Fig. 5 and 6 represents significantly different egg samples). While the maximum values for eggshell strength were obtained for unwashed eggs in compare with washed eggs at all three temperatures within whole storage time.

Further, after removing the cuticle layer, the eggshell of washed eggs become weaker in comparison with the unwashed eggs where the cuticle layer was not removed. In general, eggshell or cuticle damage has been reported after egg washing and sanitization with chemicals such as sodium carbonate, cetylpyridinium chloride, trisodium phosphate, and sodium hypochlorite (Kim and Slavik, 1996; Wang and Slavik, 1998; Favier et al., 2000). Therefore, the parameters for measuring the eggshell strength in washed and unwashed are affected by the storage environment. In addition, the highest values for maximum load and extension (Fig. 5 and 6) was obtained for unwashed eggs for all temperatures. In addition, the egg samples stored at high temperature (25℃) starts to deteriorates early in contrast with low temperature (5 and 10℃). Thus, the obtained result allows concluding that all the washed and unwashed eggs show a significant difference (p < 0.05) after certain weeks. Moreover, washed eggs in compare with unwashed eggs were slightly influenced under all storage conditions for maximum load and extension which were used for measuring the eggshell strength.

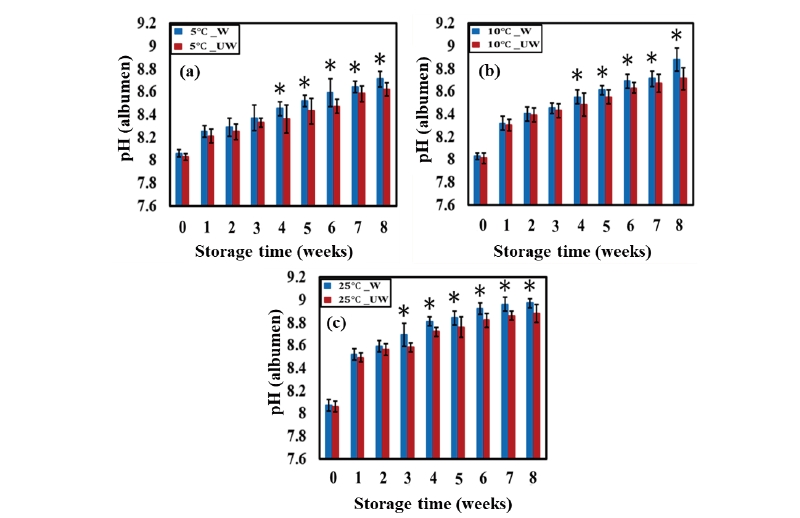

Changes in pH value during storage

The rise in the pH values of the eggs possibly a result of the loss of carbon dioxide from the egg through the pores in the shells. Further, these changes in the pH of albumen are also an important indicator of quality and are associated with the weight of the vitelline layer and reduction in the protein and hexosamine content of eggs (Akyurek and Okur, 2001). Thus, the graphical representations of changes in albumen pH at the three temperatures and different storage times (weeks) for washed and unwashed egg samples are shown in Fig. 7. A significant difference (p < 0.05) (asterisks in Fig. 7 represents significantly different egg samples) was obtained where at low temperature (5 and 10℃), changes were observed after third weeks, while for high temperature (25℃), these differences were seen after second weeks. Moreover, these observed pH values for albumen were greater at high temperature (25℃) in washed eggs in compare with unwashed eggs at a lower temperature (5 and 10℃).

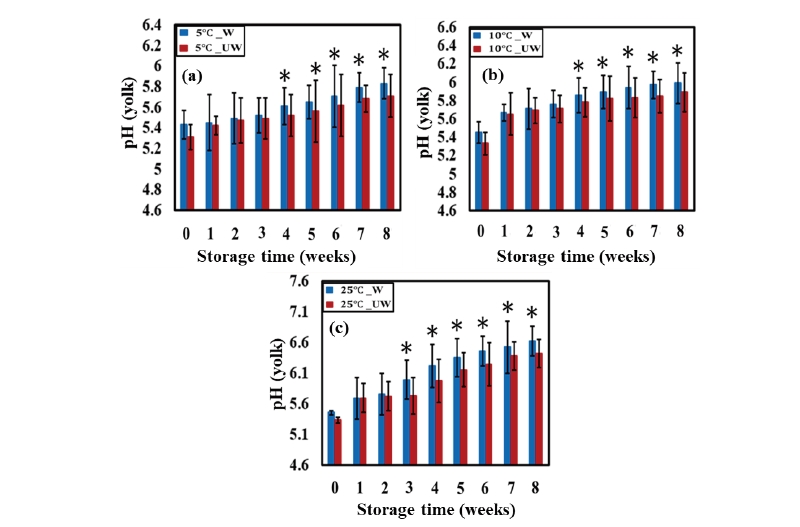

The increase in pH of the yolk in eggs also attributed to the loss of carbon dioxide and moisture from the eggs through the pores in the shell resulting from dilution of the egg yolk. With the increase in the storage temperature, the internal temperature of the egg increases, and leads to increase in the yolk pH (Jones, 2006). Therefore, these changes in yolk pH at the three temperatures and different storage times (weeks) for washed and unwashed egg samples were represented in Fig. 8. A significance difference (p < 0.05) was obtained for low temperature (5 and 10℃) after third week, while these differences for high temperature (25℃) were observed after second week in washed and unwashed eggs (asterisks in Fig. 8 represents significantly different egg samples). While greater values for yolk pH were extracted from washed eggs at a higher temperature in contrast with unwashed eggs.

Storing egg samples at a high temperature (25℃) show higher pH values when compared to those stored at low temperature (5 and 10℃). Moreover, storage of washed and unwashed samples at a higher temperature demonstrated earlier changes in the pH values for both albumen and yolk compared to those of egg samples stored at a lower temperature. In addition, a study was concluded that a significant increase (p < 0.05) was observed in the pH of the albumen and yolk with increasing storage time (Akyurek and Okur, 2001). Therefore, the quality of washed eggs shows a more pronounced dependence on storage condition confirmed by higher pH values measured for both albumen and yolk, as compared with unwashed eggs.

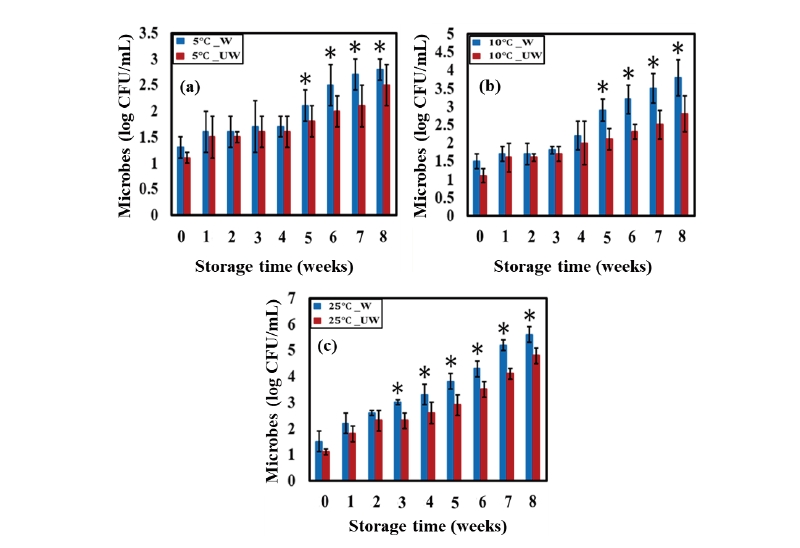

Changes in microbiological properties during storage

An increase in the number of microbes is observed owing to the cuticle layer on the surface of the shells of eggs stored at a high temperature. The changes in microbial growth were graphically represented in Fig. 9 for different storage time (weeks) and temperature for washed and unwashed egg samples. The result interpreted by ANOVA shows a significant difference (p < 0.05) for all washed and unwashed eggs at specific week (asterisks in Fig. 9 represents significantly different egg samples). For low temperature samples (5 and 10℃), these changes were observed after the fourth week, while at high temperature (25℃) these differences were seen after two weeks. Further, the most considerable microbial growth was being observed in the washed eggs at high temperature in contrast with unwashed eggs at low temperature.

A breakdown in the vitelline layer occurs when egg samples are stored at a high temperature. As this layer dries up quickly, it begins to shrink leading to an increase in the shell pore size and the passage of microorganisms through the shell. As the membrane degenerates with an increase in the storage period, water enters the yolk in the form of moisture, and the shell pores then open for microorganisms to enter (Ahn et al., 1999).

Thus, the highest microbial population was observed at a high temperature while the growth rate was slower at a lower temperature in washed and unwashed eggs. In addition, washed eggs were profoundly influenced by the storage environment condition, as extracted information showed that microbe population growth was higher in washed eggs in contrast with unwashed eggs. Thus, we concluded that storing eggs at higher temperature leads to an increase in the microbial growth that deteriorates the quality of eggs, which are then not suitable for human consumption.

Conclusion

Quality or freshness parameters measured in washed and unwashed eggs stored at different storage time (0 - 8 weeks) and temperatures (5, 10, and 25℃) were influenced by these storage environments. All the parameters show significant differences (p < 0.05) between washed and unwashed eggs, within a specific storage interval. In HU, decline in the values while for airspace volume, the increment was also observed in the washed eggs in compare with unwashed eggs at low temperature (5 and 10℃). In addition, no changes were observed at high temperature (25℃), as storing washed or unwashed eggs can deteriorate the quality of eggs. Further, the pH of albumen and yolk, and eggshell strength also provide information regarding the consequences of storage condition. Indeed, these parameters are also affected by storing eggs at high temperature for a long time. Besides, microbial growth shows a decline when eggs were stored at a low temperature while increases drastically at high temperature.

Therefore, this study provides fundamental information that can further be used for analyzing the storage effects on the quality of eggs. These changes in the egg quality during different storage time and temperature are significantly affected for all parameters. Thus, the presented study concluded that storage time and temperature are also critical factors that affect the quality of eggs. Consequently, we observed that the quality parameters in washed eggs are more susceptible to the storage environment condition when we draw a comparison with unwashed eggs.

Acknowledgement

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture, Forestry and Fisheries (IPET) through Agriculture, Food and Rural Affairs Research Center Support Program, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA), Republic of Korea (No. 717001071WT111).

Authors Information

Ritu Joshi, Chungnam National University, Department of Biosystems Machinery Engineering, College of Agricultural and Life Science, Ph.D. student

Rahul Joshi, Chungnam National University, Department of Biosystems Machinery Engineering, College of Agricultural and Life Science, Ph.D. student

Mohammad Akbar Faqeerzada, Chungnam National University, Department of Biosystems Machinery Engineering, College of Agricultural and Life Science, Ph.D. student

Eunsoo Park, Chungnam National University, Department of Biosystems Machinery Engineering, College of Agricultural and Life Science, Ph.D. student

Hyungjin Bae, Chungnam National University, Department of Biosystems Machinery Engineering, College of Agricultural and Life Science, Ph.D. student

Jayoung Lee, Chungnam National University, Department of Biosystems Machinery Engineering, College of Agricultural and Life Science, Master student

Hyeon Tae Kim, Gyeongsang National University, Department of Biosystems Engineering, College of Agricultural and Life Science, Professor

Byoung-Kwan Cho, https://orcid.org/0000-0002-8397-9853